3D printing has revolutionized the world of manufacturing and prototyping. At ELOPRINT, we are proud to utilize a wide range of advanced 3D printing methods to provide our customers with high-quality test jigs and electronic solutions. In this blog post, we would like to introduce you to our various 3D printing techniques, which enable us to create unique products.

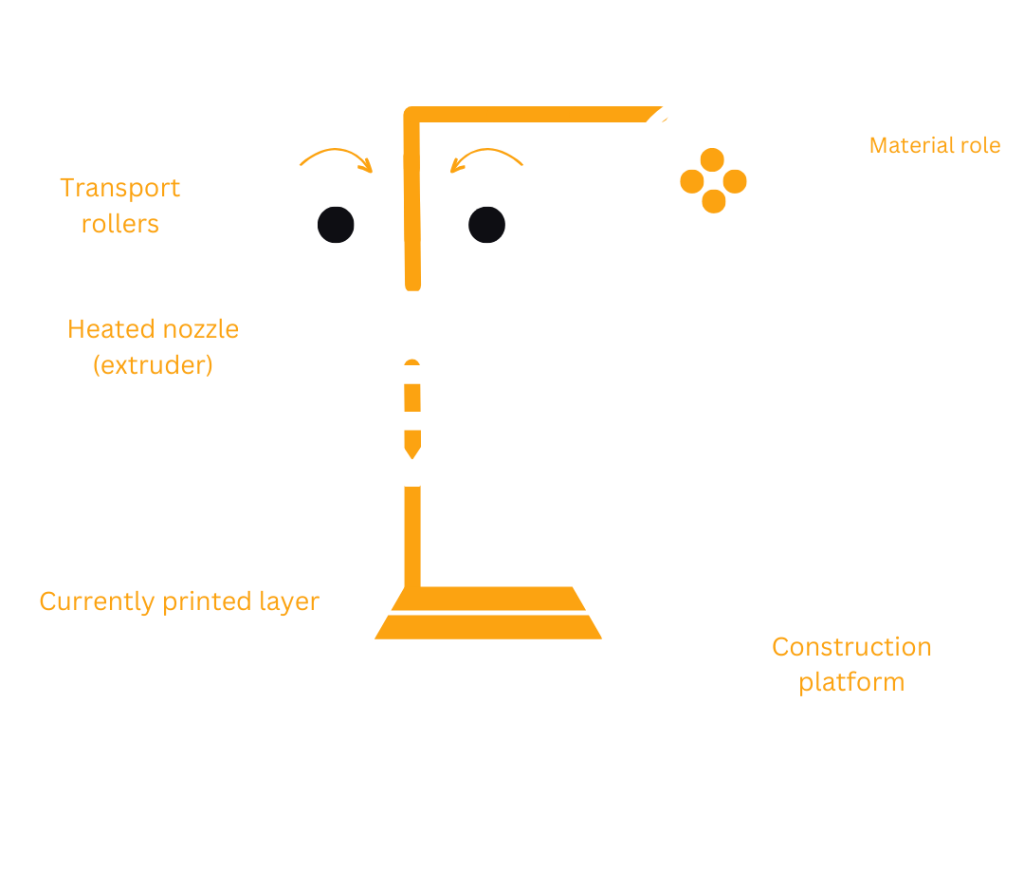

FDM (Fused Deposition Modeling): Efficiency from Melted Material

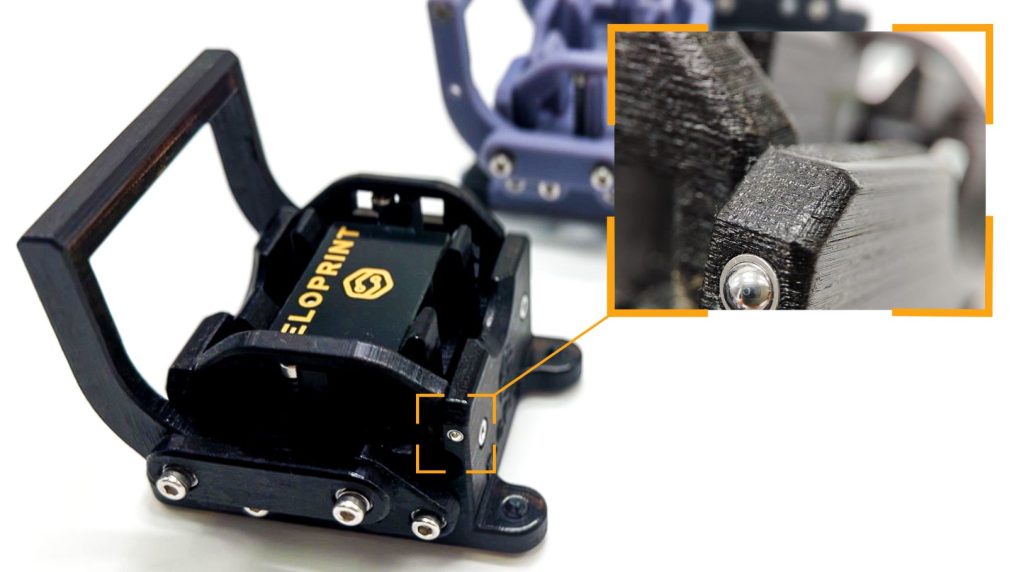

For FDM parts, the characteristic surface is linear. These parts are not isotropic, meaning they are not equally strong in all directions because the individual layers do not fuse as well together as the paths within the same plane. The design must already consider the orientation in which the part will be printed to account for the resulting weak points.

We typically work with a nozzle diameter of 0.4 mm and a layer thickness of 0.16 mm. Compared to other additive processes, this is relatively coarse and limits the level of detail and precision.

For FDM parts, the characteristic surface is linear. These parts are not isotropic, meaning they are not equally strong in all directions because the individual layers do not fuse as well together as the paths within the same plane. The design must already consider the orientation in which the part will be printed to account for the resulting weak points.

We typically work with a nozzle diameter of 0.4 mm and a layer thickness of 0.16 mm. Compared to other additive processes, this is relatively coarse and limits the level of detail and precision.

Advantages

- Cost Efficiency: Low printing costs and affordable materials.

- Material Variety: Usable with various thermoplastics like PLA, ABS, PETG, PC.

- Ease of Use: User-friendly printers, suitable for beginners.

- Environmental Friendliness: Use of biodegradable PLA material is possible.

- Minimal or No Post-Processing: Little to no post-processing of parts required.

Disadvantages

- Surface Quality: Visible layer lines and rough surfaces.

- Slow Printing Process

- Limitations in Dimensional Tolerance and Detail Accuracy

- Restricted Geometric Freedom: Printing overhangs is problematic.

- Non-Isotropic Parts

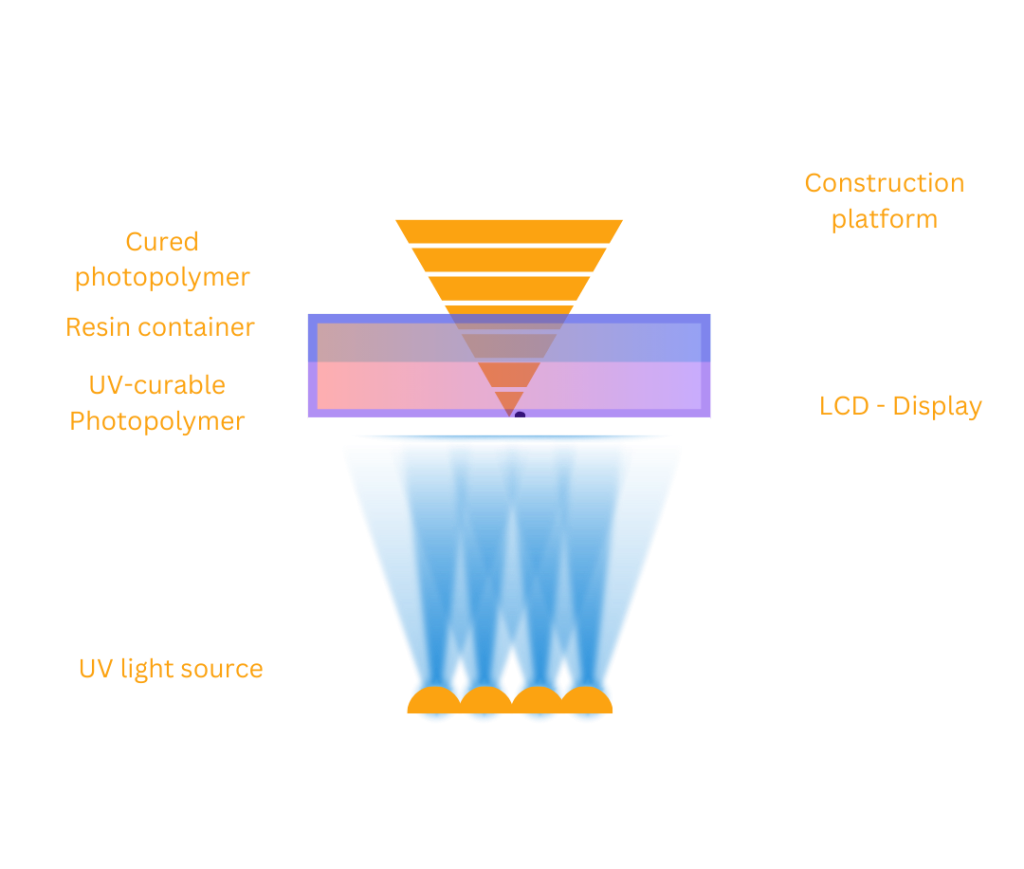

MSLA (Masked Stereolithography): Highest Detail Accuracy with Photopolymers

Fused Deposition Modeling (FDM) is one of the most commonly used 3D printing methods. In this process, molten plastic is extruded through a heated nozzle and deposited layer by layer to form the desired object. The advantages of FDM are particularly evident in its material versatility: unlike many other methods, FDM is not limited to a specific material. This allows for the selection of various thermoplastics tailored to the specific application. For example, PLA (Polylactic Acid), a plastic made from renewable resources, can be chosen for cost-sensitive applications. TPU (Thermoplastic Polyurethane) can be used for flexible parts, while ABS (Acrylonitrile Butadiene Styrene) is suitable for applications in high temperatures. Additionally, FDM 3D printers and the required raw materials are relatively affordable and easy to handle.

In principle, entire test jigs can be manufactured using the MSLA process. However, as the adapter size increases, the risk of issues such as warping or material failure also increases. Although the surface quality is visually superior, we do not offer full adapter production in this material. Instead, we use MSLA as a complement for selected components where small structures need to be as precise as possible—such as carrier plates where very small test specimens need to be accurately positioned.

Advantages

- High Precision: Capable of producing very fine details and smooth surfaces.

- Versatile Resins: Selection of specialized resins for various applications.

- Fast Curing: Efficient printing process through simultaneous curing of entire layers.

Disadvantages

- Surface Quality: Visible layer lines and rough surfaces.

- Strength: Often lower mechanical strength compared to injection molding.

- Printing Speed: Slower printing process with complex geometries.

- Accuracy: Limitations in dimensional tolerance and detail accuracy.

- Heat Resistance: Limited heat resistance of printed parts, depending on the material.

- Material Properties: Limitations due to the properties of thermoplastics.

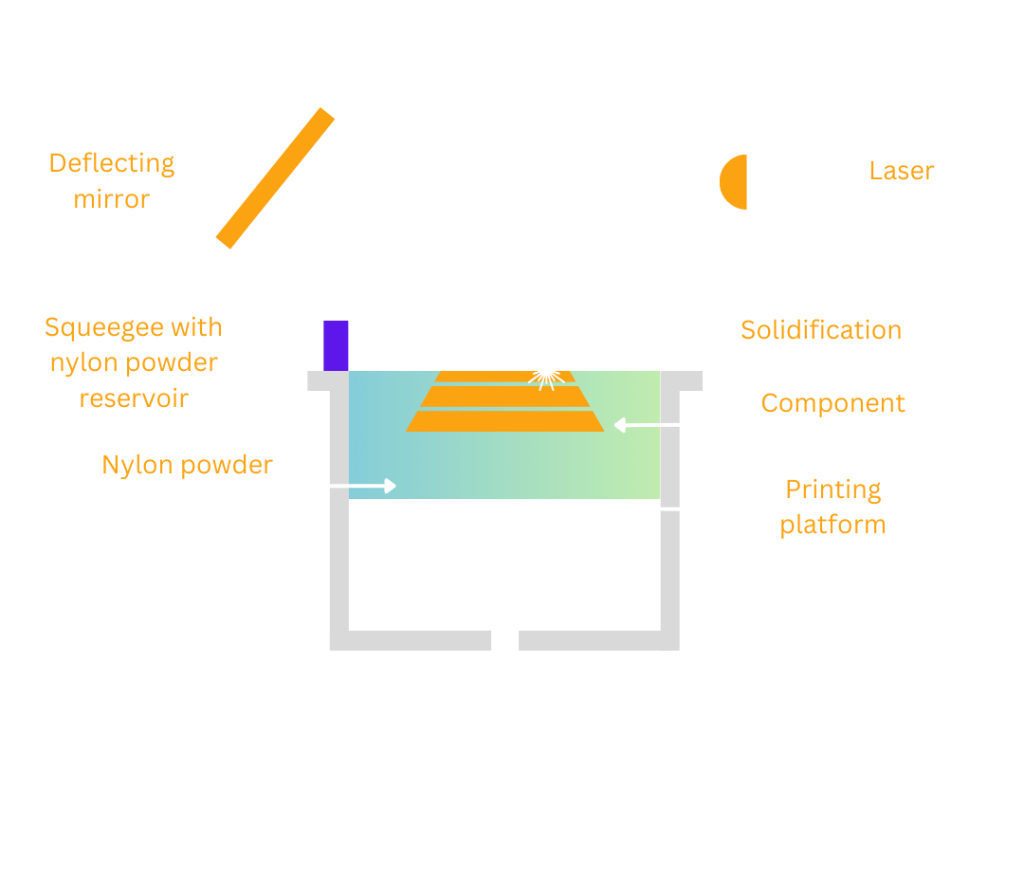

SLS (Selective Laser Sintering): High Strength and Precision

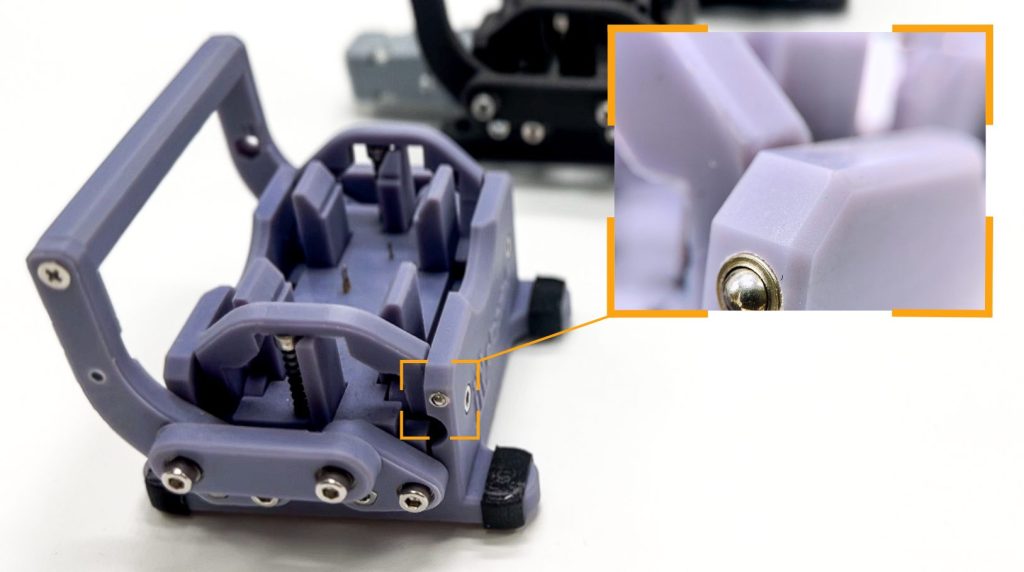

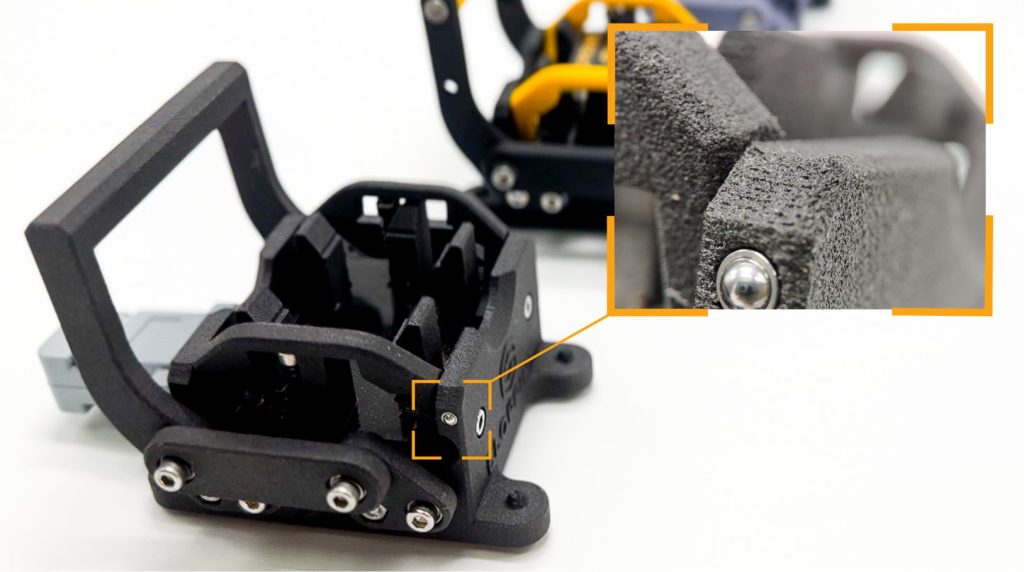

The SLS (Selective Laser Sintering) process is one of the most widely used methods in the industry. It employs a powerful laser to fuse fine plastic powder particles layer by layer, creating three-dimensional objects. This process offers high strength, precision, and the capability to produce complex geometric shapes. Overhangs can be easily manufactured as they are supported by the powder bed, eliminating the need for dedicated support structures. PA12 (Polyamide), commonly known as Nylon, is frequently used—a technical plastic with excellent properties for general-purpose applications. After the printing process, parts must be meticulously cleaned of excess powder and subsequently sandblasted. SLS-manufactured test jigs are robust and can withstand the high mechanical stresses encountered when contacting hundreds of test points.

Parts manufactured using the SLS process have a characteristic granular surface that appears very high-quality both visually and to the touch. In close-up views, there may be an impression that the material could be porous internally, but this impression is misleading. The parts are 100% solid and waterproof.

Advantages

- Complex Geometries: No support structures needed, enabling intricate designs.

- High Strength: Very robust and durable parts.

- Detail Accuracy: High precision for small and complex components.

- Heat Resistance: Parts can withstand high temperatures, depending on the material.

Disadvantages

- Cost: Higher equipment, printing, and material costs compared to FDM.

- Surface Roughness: Although the surfaces are high-quality, they have poor frictional properties.

- Printing Speed: Longer printing times due to extended heating and cooling periods.

- Post-Processing: Excess powder needs to be meticulously removed.

Inkjet: Inkjet Printing for Complex Designs

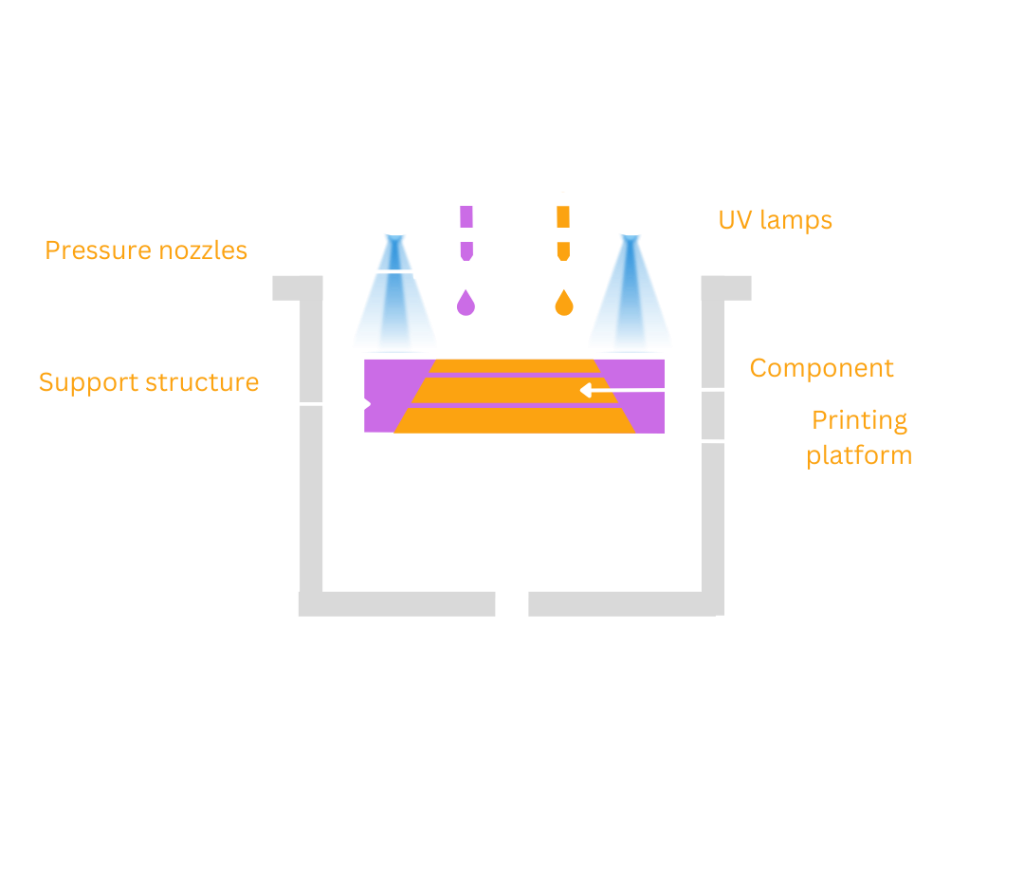

In inkjet 3D printing, a liquid photopolymer is applied to a build platform in the form of microscopic droplets, similar to how ink is used in traditional inkjet printers. The unique aspect of this plastic is that it cures through a chemical reaction when exposed to UV light. Therefore, the inkjet printer uses a UV lamp to cure the printed droplets after each layer is applied.

The key advantage of this process is the ability to print not only the build material but also a water-soluble support material. This allows for the complete enclosure of complex and overhanging geometries in support material, enabling the creation of almost any geometry with the highest precision. Inkjet technology thus offers the flexibility to produce test jigs tailored to our customers’ specific requirements, delivering high-quality solutions. The support material can be easily removed after the printing process in a water ultrasonic bath.

Only a few manufacturers worldwide master inkjet technology, and their machines can differ significantly. We have chosen equipment from Keyence for our needs. Other manufacturers specialize in particularly high-quality surfaces or multi-color printing. However, for us, reliability and material properties were the primary considerations. Do not be misled by the irregular-looking lines; these are merely optical imperfections. The parts are manufactured within the micrometer range. Unfortunately, both the equipment costs and material costs are significantly higher—about 20 times more—compared to FDM printers. Therefore, we use this method only for geometries that cannot be produced by other techniques.

Advantages

- Highest Precision: Very fine details and smooth surfaces achievable.

- Minimal Post-Processing: Simple post-process with parts fitting correctly from the start.

- Material Variety: Selection of materials with different properties.

- Fast Printing Process: Efficient printing speed through simultaneous curing of entire layers.

Disadvantages

- Cost: Higher material and equipment costs compared to FDM.

- Sensitivity: Printed parts may be brittle and prone to cracks or fractures.